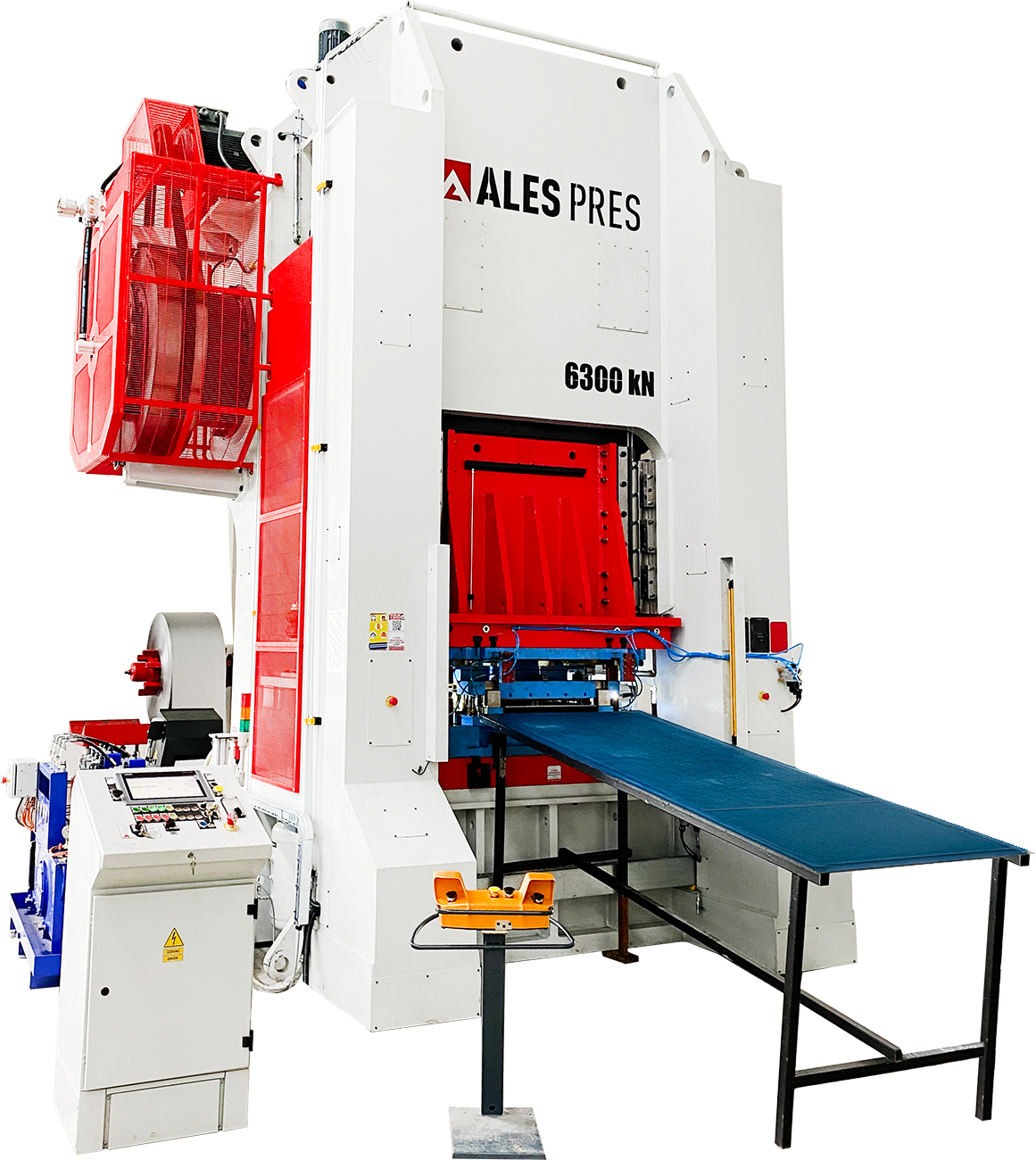

Ales Pres Delivers 630-Ton Knuckle Joint Eccentric Press to Sakra

As Ales Pres, we continue to offer customized engineering services in the field of high-tonnage eccentric press systems and special…

Knuckle joint press machines are an optimized type of eccentric press systems, ideal for applications requiring high precision. They are widely used in deep drawing, sensitive part forming, and operations needing maximum die protection. At ALES PRES, we provide expert solutions in this field.

Why Choose ALES PRES Knuckle Joint Press Machines?

Application Areas

As Ales Pres, we continue to offer customized engineering services in the field of high-tonnage eccentric press systems and special…

A knuckle joint press is a special type of press that plays a significant role in metalworking and shaping processes.…

Our 800-ton Knuckle Joint type eccentric press, specially engineered for panel radiator production at the Demirdöküm plant in Eskişehir.

| Feature | Value |

| Mechanism | Knuckle Joint (Articulated Linkage System) |

| Drive Type | Mechanical drive (“Eccentric shaft or Gear-to-Eccentric” system) |

| Capacity | From 100 tons up to 2,500 tons (custom-built upon request) |

| Stroke Length | From 50 mm to 150 mm (custom-built upon request) |

| Stroke Rate | From 10 spm to 80 spm (custom-built upon request) |

| Number of Pressure Points | 2 or 4 connecting rods, depending on press type |

| Table Size | From 1,000 mm to 6,500 mm (custom-built upon request) |

| Optional Features | Anti-vibration springs, movable safety guards, quick die change systems (QDCS), sound insulation cabin |

At ALES PRES, we integrate knuckle joint press systems with eccentric press technology to offer maximum performance and precision. We support your deep drawing and precision forming projects with expert engineering.

It’s a type of mechanical press that uses a knuckle joint mechanism, which delivers high force near the end of the stroke. It’s commonly used in deep drawing and precision forming applications.

Knuckle joint presses wait longer and apply more force at the bottom dead center than eccentric presses. They are slower but more precise.

Ideal for deep drawing, panel radiator production, coin minting, powder metal forming, and gear surface shaping—applications that need both force and precision.

They are slower than eccentric presses, not suitable for continuous high-speed stamping, and require more maintenance due to their complex joint mechanism.

No. Like all presses, it should ideally run at 70–80% of its capacity for longer life. Full tonnage should only be used briefly.

In most knuckle joint presses, the stroke is fixed.

The knuckle joint slows down as it nears the bottom, almost locking in place. This creates a mechanical advantage, generating very high force at the bottom.

No. Due to their design, they work slowly—usually between 10 and 80 strokes per minute.

The joints, arms, and pins must be regularly lubricated and checked for looseness. Poor maintenance can cause misalignment.

They are generally quieter than other mechanical presses due to less vibration, but hearing protection is still needed above 80 dB.

Used in panel radiator manufacturing, automotive parts, home appliances, watchmaking, coin minting, powder metallurgy, medical implants, and thin-wall aluminum parts.

No. They’re not suited for impact operations like cutting or punching. They’re better for forming and drawing.

Look at frame structure, stroke length, speed, bottom dwell time, joint quality, lubrication type, and automation options.

Yes, newer models may use servo motors for better precision and energy savings—but this is rare. Direct servo presses are usually preferred.

Servo types allow adjustable stroke and pressing time, offering better precision and lower energy use.

Forming, deep drawing, and shaping are ideal. For cutting, eccentric presses are better.

Yes. Standards like EN 692, EN ISO 12100, and EN ISO 13849 apply to both.

Staying longer at the bottom helps fully form the part, improving surface finish and extending die life.

Yes, on modern presses. Older models usually require manual or semi-automatic die change.

Only on servo-controlled models. In traditional presses, mechanical limits apply, and the mechanism must be redesigned to change it.

Very little. The long pressing time at bottom helps the material fit the die better, reducing springback.

Yes, pins and bearings can wear. Regular lubrication and clearance checks are necessary to prevent problems.

Unlike a sinusoidal curve, force increases as speed drops at the end of the stroke, resulting in better forming quality.